SIEMENS TRACTION TRANSFORMERS-TRACTRONIC®

SIEMENS Traction Transformers Tractronic : Designing and manufacturing traction transformers for rail operators and train manufacturers worldwide, Siemens produces TT transformers that increase train efficiency and performance – handle highest ratings in a minimum of available space – serve local content demands for worldwide application – afford maximum reliability and flexibility.

Compact, light and efficient

Siemens develops and produces traction transformers for rolling stock applications of all relevant ratings and voltage levels. The focus is on maximum reliability, economic efficiency and safety – and ensuring that the transformers are perfectly in line with the customer’s requirements.

Design options

- power ratings – frequency, capacity and voltage

- size, weight and place of installation

- dissipation and short-circuit voltages

- losses and impedance voltage characteristics

- driving patterns and medium-frequency performance

- materials and technologies to meet environmental requirements (e.g. ester coolant)

Leveraging data for maximum transformer performance

Siemens Transformers offers the opportunity to track the transformers in operation. Operators can not only monitor but optimize transformer performance. Monitoring and data analysis are the important factors for digitalization of traction transformer for rollingstock applications.

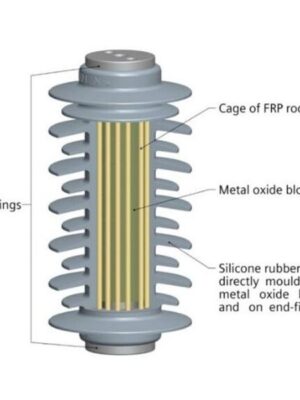

A new generation of sensors monitors transformer health

A modular multisensory system continuously monitors the “health” status of the transformer and modifies operation behavior according to the results of an onboard optimization algorithm. The Siemens monitoring system leverages a new generation of sensors. These sensors transmit data to a local, remote or cloud-based control system. After data processing, the actors will – if necessary – receive commands for correcting the operation behavior.

Benefit from the performance data of other traction transformers

Economical and technical information of each traction transformer is updated online and collected to optimize all similar transformers in operation. Our real-time monitoring system optimizes cost of operation cost and maintenance intervals, increasing energy and economic efficiency.

Rely on Siemens Transformers – anywhere, anytime

Siemens traction transformers operates a worldwide manufacturing and service network to serve customers all over the world. Their more than 20 manufacturing sites worldwide adhere to European quality and sustainability standards – regardless of the manufacturing location.

The top 3 customer benefits of Siemens strong global presence

timely responses to inquiries,

short processing time on spare parts orders,

fast access to services directly on-site.

This ensures that customers can rely on Siemens traction transformer, components and services, anywhere, anytime.

Developed, tested and certified

Siemens traction transformers are setting standards of quality and versatility around the world. Close cooperations with international standards committees guarantee the compliance with the specific requirements and standards.

Siemens is a founding member of the IRIS Initiative, and consistently implements its requirements. Our railway components comply with all the relevant standards, for example: DIN, EN, IEC, IEEE, ISO, EAC / GOST and ANSI, as well as the current fire protection standard EN 45545. With our certified components, we actively support the worldwide vehicle approval process; hence our traction transformers comply with all relevant standards, for example:

- DIN EN ISO 9001

- DIN EN ISO 14001

- OHSAS 18001

- EN 15085-2 CL 1

- GOST

- IRIS

Siemens Traction Transformers Tractronic : Siemens Transmission Products

Leader in innovations with comprehensive, connective and sustainable portfolio

Transmission products play a vital role in the energy value chain. Siemens Transmission Products provides all key elements including power transformers and distribution transformers as well as gas-insulated and air-insulated switchgear and components. Products are offered individually, bundled or with related engineering upgrade to systems. Our products offer low life cycle costs with maximum availability, highest efficiency and short commissioning times.

We are driving technology innovations not only regarding the performance of transmission products but also in the area of sustainability and eco efficiency. By merging physics and data we enable new products and applications: Sensformer® and Sensgear®. With our global factory network and leading innovations we provide the highest level of quality and reliability to our customers: TSOs, DSOs, power producers, EPCs and industrial companies.

Reviews

There are no reviews yet.